+91 9820814560

A860 WPHY 56 pipe fittings are critical components in high-pressure pipeline systems, particularly in the oil, gas, and petrochemical sectors. The letters "WPHY" stand for Wrought High-Yield, while the number 56 represents a minimum yield strength of 56,000 psi. These fittings are precisely designed to withstand the rigorous requirements of transferring fluids under high pressure and in harsh locations. These fittings are manufactured in compliance with the ASTM A860 standard, which guarantees good mechanical properties such as high tensile strength and great impact resistance. WPHY 56 pipe fittings come in a variety of shapes and sizes, including elbows, tees, reducers, and caps, making them suitable for a wide range of pipeline layouts and diameters. This versatility allows them to be smoothly integrated into a wide range of industrial applications, from small-scale operations to large-scale undertakings.

The high-yield strength low-alloy steel used in WPHY 56 fittings is highly resistant to corrosion and mechanical stress. This resilience is critical for sustaining the structural integrity of pipeline systems, especially in harsh settings such as offshore oil platforms and chemical facilities. The sturdy structure of these fittings assures a long service life, reducing the need for regular replacements and maintenance, making them both cost-effective and operationally efficient. A860 WPHY 56 pipe fittings are commonly used in high-pressure pipeline systems in the oil and gas industries. They are also commonly utilized in petrochemical plants, power generation facilities, and industrial pipe systems. Their capacity to endure high pressure and corrosion makes them suitable for delivering oil, gas, and other fluids in a safe and efficient manner. Furthermore, their great strength and durability are critical in situations where pipeline failure is not an option because to the risk of serious safety concerns and financial losses.

The key advantages of A860 WPHY 56 pipe fittings are their great strength, longevity, and resistance to harsh environments. These characteristics make them a trustworthy choice for important applications, assuring the safe and efficient functioning of pipelines. Their design and material qualities strike a compromise between strength and flexibility, allowing them to withstand the stresses and strains of high-pressure settings.

Specification : ASTM A860 / ASME SA860

Dimension Standard : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : 1/8” NB TO 48” NB.

Thickness : 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75

Type : Seamless / Welded / Fabricated

Bending Radius : R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM A860 Carbon Steel WPHY 56 Pipe Fittings at Best Price.

Call : +91-9820814560 or Send Enquiry

Carbon Steel WPHY 56 Pipe Elbow

Carbon Steel WPHY 56 Concentric Reducer

Carbon Steel WPHY 56 Eccentric Reducer

Carbon Steel WPHY 56 Equal Tee

Carbon Steel WPHY 56 Cross

Carbon Steel WPHY 56 Pipe Cap

Carbon Steel WPHY 56 Pipe Bend

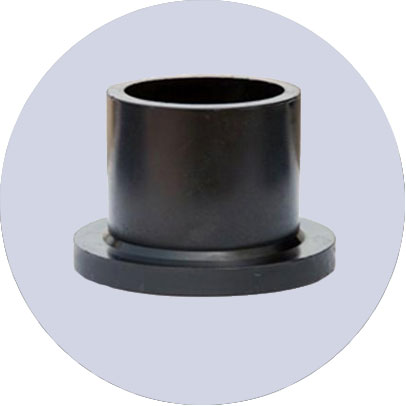

Carbon Steel WPHY 56 Stub End

Carbon Steel WPHY 56 Pipe Fittings

ASME SA860 WPHY 56 Carbon Steel Stub End

Carbon WPHY 56 Concentric Reducer Supplier

A860 WPHY 56 Carbon Steel Reducer

Carbon Steel WPHY 56 Pipe Elbow

Carbon Steel WPHY 56 End Pipe Cap Stockist

ASTM A860 Carbon WPHY 56 Equal Tee

ASME B16.9 WPHY 56 Carbon Steel Pipe Bend

Carbon Steel WPHY 56 Butt weld Fittings

WPHY 56 Carbon Steel Dish Cap Exporter

Carbon Steel ASTM A860 WPHY 56 45 deg. Elbow

WPHY 56 Carbon Steel Cross

Carbon Steel WPHY 56 90degree Elbow

Carbon Steel WPHY 56 Long Stub End Specification

Carbon Steel WPHY 56 Seamless Pipe Fittings

ASTM A860 WPHY 56 Carbon LR ELbow Manufacturer

Carbon Steel WPHY 56 Pipe Nipple

Carbon Steel WPHY 56 SR Elbow Distributor

Carbon WPHY 56 Butt weld Pipe Fittings Dealer

Carbon Steel A860 WPHY 56 Butt weld Elbow

Carbon Steel WPHY 56 Buttweld Fittings Price

Carbon Steel WPHY 56 Welded Pipe Fittings

Carbon Steel A860 Reducing Tee

ASTM A860 WPHY 56 Carbon Steel 180 deg. Bend

Carbon Steel WPHY 56 Reducing Elbow

Carbon Steel WPHY 56 U Bend

Carbon Steel WPHY 56 Eccentric Reducer

Carbon Steel WPHY 56 Collar Pipe Fittings

We have regular exports of Carbon Steel WPHY 56 Butt weld Fittings in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of ASTM A860 Carbon Steel WPHY 56 Butt weld Pipe Fittings in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.