+91 9820814560

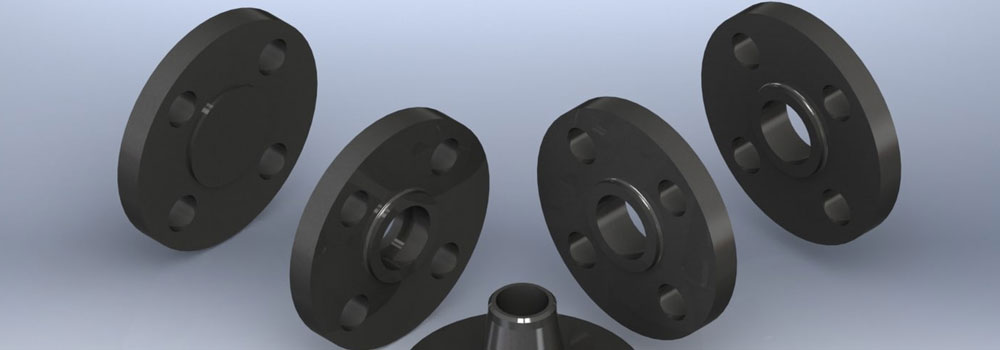

In several industrial applications, forged flanges are a kind of mechanical part that joins pipes, valves, pumps, and other machinery. They are made using the forging process, which uses compressive pressures to shape metal. When compared to alternative manufacturing procedures like casting, this technology offers higher strength and endurance. A billet of metal, often steel, stainless steel, or alloy steel, is heated to a high temperature at the start of the forging process. As a result, the metal is more pliable and moldable. After that, the heated billet is put into a die or mold and hammered or pressed under high pressure. The metal is shaped into the correct flange shape by this compressive force. In order to achieve precise dimensions and performance criteria, the forging flange is cooled and frequently goes through additional operations like machining, heat treatment, or surface finishing.

Compared to cast or welded flanges, forged flanges provide a number of advantages. Because of the homogeneous grain structure that is achieved during the forging process, they have outstanding mechanical qualities. Increased tensile strength, impact resistance, and general durability are the outcomes of this. In addition to their superior fatigue resistance, forged flanges can tolerate high temperatures and pressures, which makes them perfect for demanding applications in sectors like chemical processing, power generation, and oil and gas extraction.

Forged flanges are frequently utilized in high-pressure and high-stress applications because of their sturdy design. They are crucial parts of the plumbing and pipeline systems that deal with liquids, gases, and steam. Furthermore, forged flanges are used in structural applications where dependability and strength are crucial. In many industrial systems, forged flanges are essential parts that offer a dependable and long-lasting way to join different parts. Demanding applications favor them because of their robustness, resilience to adverse environments, and capacity to tolerate elevated pressures.

Dimension Standard : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size : ½" (15 NB) to 48" (1200NB)

Class / Pressure Rating : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

DIN : IN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

BS : BS4504 , BS4504, BS1560, BS10

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

ASTM A182 – ASME SA182 : Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

ASME B16.5 : Pipe Flanges and Flanged Fittings

ASME B16.36 : Orifice Flanges

ASME B16.47 : Large Diameter Steel Flanges NPS26 Through NPS60

MSS SP-6 : Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves and Fittings

| Stainless Steel Forged Flanges | |

| ASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904L | |

| Carbon Steel Forged Flanges | |

| ASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70 | |

| Alloy Steel Forged Flanges | |

| ASTM A182, F1, F5, F9, F11, F22, F91 | |

| Duplex Steel Forged Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| Super Duplex Forged Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| High Nickel Alloy Forged Flanges | |

| ASTM B564, B160, B472, B162, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade 2 & 5), Cupro-Nickel 70/30, Cupro-Nickel 90/10. | |

| Low Temperature Carbon Steel Forged Flanges | |

| ASTM A350, LF2, LF3 | |

A Wide Range of ANSI B16.5 Forged Flanges at Best Price.

Call : +91-9820814560 or Send Enquiry

Forged Flanges are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a wide range of Forged Flanges through a worldwide network of stock-keeping branches. These ASME B16.5 Forged Flanges is use in various industries like :

Stainless Steel Forged Flanges use in Oil and Gas Industry

ASTM B16.5 Forged Flanges use in Petrochemical Industry

Forged Flanges Used In Refineries Industry

Forged Flanges use in Nuclear Power Plant Industry

Alloy Steel Forged Flanges use in Chemical Industry

ANSI B16.5 Carbon Steel Forged Flanges use in Marine Industry

Duplex Steel Forged Flanges use in Aerospace Industries

Nickel Alloy Forged Flanges use in Pulp & Paper Indusry

Forged Flanges

ASME B16.5 Forged Flanges

Stainless Steel Forged Flanges

ASTM A403 SS Forged Flanges

ANSI/ ASME B 16.5 Forged Flanges Stockist

ANSI B16.5 Forged Flanges Supplier

ASME/ANSI B16.5 Forged Flange

Carbon Steel Forged Flanges

ASME B16.5 Class 150 Forged Flanges

Duplex Steel 2205 Forged Flanges Exporter

Super Duplex 2507 Forged Flanges

PN16/3 Forged Flange

Alloy Steel Forged Flanges Manufacturer

ANSI B16.5 Forged Flanges Distributor

Monel Forged Flange

ASME B16.5 Forged Flanges

ASME B16.5 Forged Flanges Price

Nickel Alloy Forged Flanges

ASME B16.5 Inconel Forged Flanges

ANSI/ASME B16.5 Hastelloy Forged Flanges

Copper Nickel Forged Flanges Dealer

Titanium Alloy Forged Flanges

We have regular exports of Forged Flanges in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of Forged Flanges in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.