+91 9820814560

High-performance nickel-iron-chromium alloys called Incoloy 800, 800H, and 800HT are employed in many industrial settings because of their exceptional resistance to oxidation and corrosion at high temperatures. These alloys work especially well in abrasive environments, including those found in the petrochemical, chemical, and power generation sectors. With 20% chromium and 30% nickel, Incoloy 800 is an alloy that has been reinforced by solid solution. It can be used in industrial ovens, heat exchangers, and furnace components because of its strong resistance to carburization and oxidation at high temperatures. Its composition makes it stable mechanically at temperatures as high as 1,200°F (650°C), which makes it an excellent option for a variety of high-temperature applications.

The improved Incoloy 800 was created especially to increase creep resistance and high-temperature strength. Because of its marginally higher carbon content than Incoloy 800H, it can withstand stress at high temperatures without losing its mechanical qualities. Applications where improved creep resistance is essential, like gas turbines, boiler components, and nuclear reactors, frequently use Incoloy 800HT.

With optimum amounts of carbon, aluminum, and titanium to offer even more strength and stability at high temperatures, Incoloy 800 is an even more refined version of Incoloy 800H/800HT. It is perfect for use in steam generators and cracking furnaces in the petrochemical industry, among other places where high-temperature performance is essential.

Pipe Specification : ASTM B163, B515 / ASME SB163, SB515

Size : 1/8″NB TO 30″NB IN

Thickness Range : 0.3mm – 50 mm

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

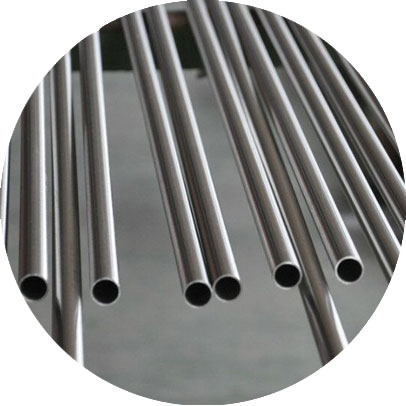

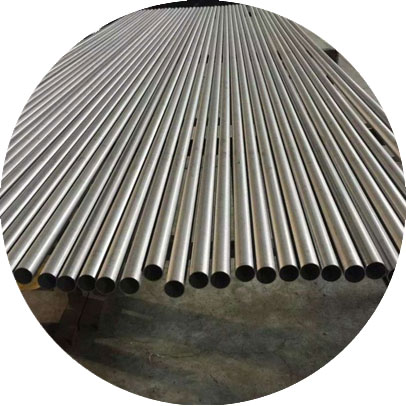

Type : Seamless Tube, Welded Tube, ERW Tube, Fabricated Tube, CDW

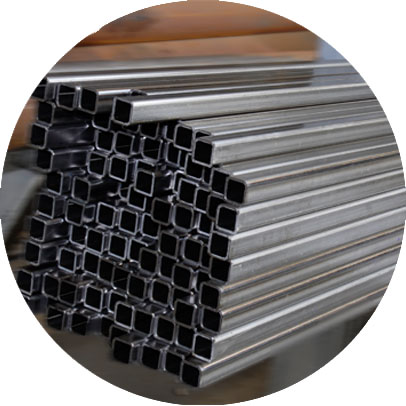

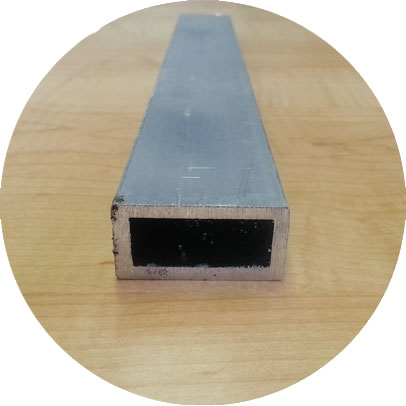

Form : Round Tubes, Square Tubes, Rectangular Tube

Length : Single Random, Double Random & Cut Length.

End : Plain End, Beveled End, Threaded

End Protection : Plastic Caps

Outside Finish : 2B, No.1, No.4, No.8 Mirror Finish

Finish : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

External Coating : 3LPE / 3LPP/ FBE/ DFBE/ PP

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM B163 / B515 Incoloy 800 / 800H / 800HT Tubes at Best Price.

Call : +91-9820814560 or Send Enquiry

Incoloy 800 / 800H / 800HT Seamless Tubes

Incoloy 800 / 800H / 800HT Welded Tubes

Incoloy 800 / 800H / 800HT Sanitary Tubes

Incoloy 800 / 800H / 800HT Bright Annealed Tubes

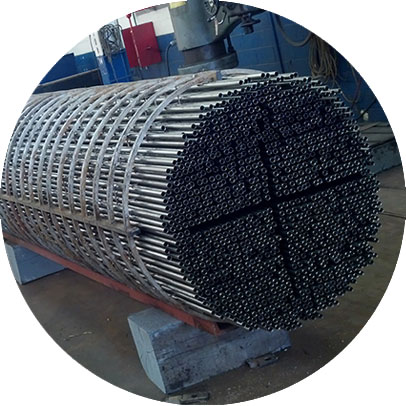

Incoloy 800 / 800H / 800HT Heat Exchanger Tubes

Incoloy 800 / 800H / 800HT Square Tubes

Incoloy 800 / 800H / 800HT Rectangular Tubing

Incoloy 800 / 800H / 800HT Round Tubes

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32 |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | - | X8NiCrAlTi32-21 | XH32T |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Incoloy 800 | 0.10 max | 1.50 max | 1.00 max | 0.015max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Incoloy 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Incoloy 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy 800 / 800H / 800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

Incoloy 800 Tubes

Best Deals on Incoloy UNS N08800 Tubes

Nickel Alloy 800 Tubing

Nickel Alloy 800 Rectangular Tubes Supplier

ASME SB163 800 Incoloy Round Tubes

Incoloy Werkstoff Nr. 1.4876 Tubes

800 Incoloy Welded Tubes

Nickel Alloy 800H Welded Tubes

Alloy 800HT ERW Tubing

ASTM B163 Incoloy 800 Cold Rolled Coiled Tube

Incoloy UNS N08810 Instrumentation Tubes

Alloy NCF 800 High Pressure Tubes Stockist

Incoloy Alloy 800 Seamless Tube

ASTM B515 Incoloy® Alloy 800 Tubing

Alloy 800 Square Tube Exporter

800 Incoloy Seamless Tubing

ASTM B515 Incoloy 800 Instrument Tubing

Nickel Alloy 1.4876 Welded Tubing

ASTM B163 Alloy 800 Seamless Tube

ASTM B515 Alloy 800 Tube

Incoloy DIN 1.4859 Seamless Tubes

Incoloy 800H High Pressure Tubes

Alloy DIN 1.4958 Heat Exchanger Tubes

Incoloy UNS N08811 Tubes

Incoloy JIS NCF 800H Sanitary Tubes

Incoloy® Alloy 800 Tubing Distributor

800 Incoloy Tubing Dealer

Incoloy 800HT ERW Tubing

ASME SB407 Incoloy 800 Exhaust Tubing

Incoloy 800 Coiled Tubing

We have regular exports of Incoloy 800 Tubes in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of ASTM B163 800 Incoloy Tube in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.