+91 9820814560

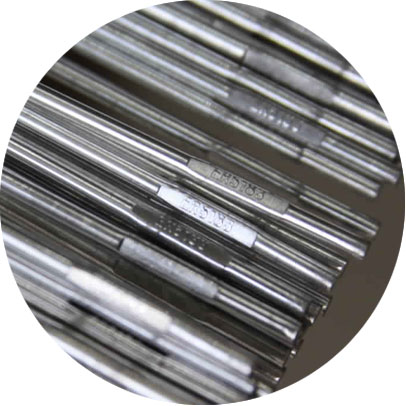

Highly renowned for its exceptional strength, resistance to corrosion, and thermal stability is the nickel-chromium superalloy Inconel 718. It is widely used in challenging environments, particularly in industrial and aviation applications. The alloy's unique composition is composed of nickel (50–55%), chromium (17–21%), iron (substantial), molybdenum (2.8–3.3%), niobium (4.75–5.5%), and trace amounts of other elements such as titanium and aluminum. Specifically, Inconel 718 wire is used in many different applications where it's essential to have great strength and resilience to harsh temperatures. It is highly prized for its capacity to preserve mechanical characteristics at temperatures as high as 1300°F (700°C), which qualifies it for usage in nuclear reactors, chemical processing, and turbine engines.

Inconel 718 in wire form is essential for a number of production processes. It can be used to make electrical contacts, high-strength springs, and other crucial parts that need to be durable and precise. The alloy's outstanding resistance to oxidation and carburization, as well as its good weldability, further increase its applicability for these kinds of uses.

To get the desired qualities, Inconel 718 wire goes through a specific heat treatment procedure. Aging and solution treatment are the next steps in this process, which help to improve the mechanical characteristics and microstructure of the alloy. The end product is a material with excellent tensile strength that can withstand harsh conditions without losing functionality.

Specification : ASTM B166 / ASME SB166

Size : 100 mm TO 6000 mm, customizable

Diameter : 10 mm To 100 mm or as per client requirement

A Wide Range of ASTM B166 Inconel 718 Wire at Best Price.

Call : +91-9820814560 or Send Enquiry

Inconel 718 Filler Wire

Inconel 718 Spring Wire

Inconel 718 Welding Electrodes

Inconel 718 Wire Bobbin

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel 718 | 2.4668 | N07718 |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015max | 0.30 max | - | 50.00 - 55.00 | 17.00 - 21.00 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

Inconel 718 Wire

Inconel 718 Filler Wire

Inconel 718 Welding Wire

ASTM B166 Alloy 718 Electrode

718 Inconel Cold Heading Wire

Inconel ASTM B166 718 Wire Bobbin

Alloy 718 Spring Wire Stockist

Inconel® Alloy 718 Electrode Wire Supplier

ASME SB166 718 Inconel Welding Electrodes

Inconel® Alloy JIS NCF 718 Wire

718 Nickel Alloy Filler Wire Exporter

718 Inconel Wire

UNS N07718 Inconel Filler Wire

Inconel 718 Bright Wire

Inconel® Alloy 718 Welding Wire Manufacturer

Alloy 718 Welding Electrodes Distributor

Inconel 718 Welding Wire

Inconel UNS N07718 Wire Price

Inconel® Alloy DIN 2.4668 Wire

718 Alloy Filler Wire Dealer

Inconel 2.4668 Spring Wire

Inconel Alloy 718 Wire

We have regular exports of Inconel 718 Electrode in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of ASTM B166 718 Inconel Wire in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.