+91 9820814560

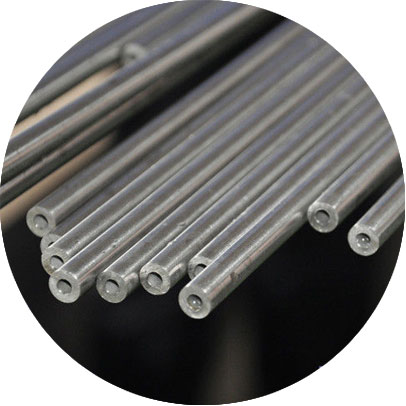

Because of their improved mechanical qualities, resistance to wear, and tolerance to high temperatures, alloy steel tubes—especially those classified as T5, T5B, and T5C—are essential to many different sectors. These tubes are frequently utilized in industrial, automotive, and aerospace machinery—applications where strength, longevity, and performance are crucial. Steel Alloy T5 Chromium, molybdenum, and occasionally vanadium are among the alloying components and heat treatment techniques that distinguish tubes. The excellent tensile strength and corrosion and abrasion resistance of the tube are attributed to these components. T5 tubes are frequently utilized in harsh settings with significant stress levels and temperature swings.

A variation of the T5 series, T5B tubes have somewhat different qualities than regular T5 tubes. The "B" designation typically denotes a difference in the heat treatment procedure or chemical composition, which might change the mechanical characteristics of the tube or enhance its performance in particular scenarios. Applications seeking a compromise between toughness and resistance to thermal fatigue may find usage for T5B tubes.

T5C Tubes are a higher tier in the T5 category, made to fulfill more exacting performance standards. A new heat treatment program or an even higher degree of alloying are frequently indicated by the "C" designation, which improves properties including tensile strength, impact resistance, and general durability. These tubes are perfect for high-performance applications and harsh conditions.

Tube Specification : ASTM A213 / ASME SA213

Size : 1/2" NB To 36" NB

Outside Diameter (OD) : 19.05mm – 114.3mm

Wall Thickness : 2.0mm – 14 mm

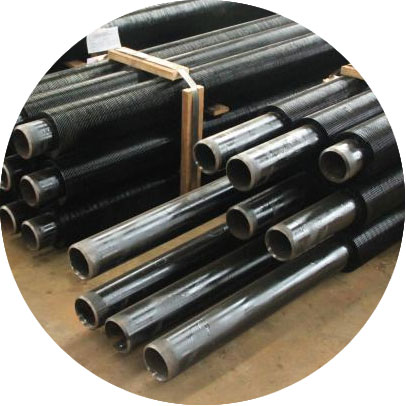

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type : Seamless / EFW / Cold Drawn / Annealed & Pickled / Hot Finished / Extruded / Structural

Form : Round Tubes

Length : Single Random, Double Random & Cut Length

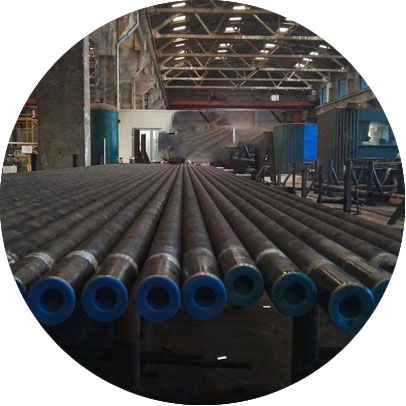

End : Plain End, Beveled End, Threaded

End Protection : Plastic Caps

Finish : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM A213 T5 / T5B / T5C Alloy Steel Tubes at Best Price.

Call : +91-9820814560 or Send Enquiry

Alloy Steel T5 / T5B / T5C Seamless Tubes

Alloy Steel T5 / T5B / T5C High Pressure Steel Tubes

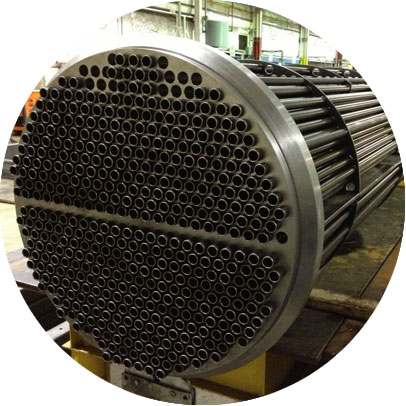

Alloy Steel T5 / T5B / T5C Heat-Exchanger Tubes

Alloy Steel T5 / T5B / T5C Superheater Tubes

Seamless Ferritic Alloy Steel T5 / T5B / T5C Tubes

Alloy Steel T5 / T5B / T5C Round Tubes

ASTM A213 T5 / T5B / T5C Chrome Moly Tubes

Alloy Steel T5 / T5B / T5C Boiler Tubes

| GRADE | UNS | TRADE NAME |

| T5 | K41545 | 5Cr-1/2Mo |

| T5B | K51545 | 5Cr-1/2Mo |

| T5C | K41245 | 5Cr-1/2Mo |

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.15 max | 0.30-0.60 | 0.025 | 0.025 max | 0.50 max | 4.00-6.00 | 0.45-0.65 |

| Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

| 415 min | 205 min | 30 min |

| Outside Diameter | OD Tolerance | WT Tolerance | Ovality Tolerance | Cut Length Tolerance |

| OD≤ 12, 7 mm | ± 0, 13 mm | ± 15 % | – | + 3, 18 mm, – 0 mm |

| 12, 7 mm < OD ≤ 38, 1 mm | ± 0, 13 mm | ± 10 % | max, 1, 65 mm | + 3, 18 mm, – 0 mm |

| 38, 1 mm < OD ≤ 88, 9 mm | ± 0, 25 mm | ± 10 % | max, 2, 41 mm | + 4, 76 mm, – 0 mm |

Alloy Steel T5 Tubes

Alloy Steel T5 Seamless Tube

Chrome Moly T5B Tubes

ASTM A213 CrMo T5 Tubing

T5 Alloy Steel Tubes

Alloy Steel ASTM A213 Gr T5 Tubes

Alloy Steel T5C Heat-Exchanger Tubes

Alloy Steel T5 Superheater Tubes Stockist

ASTM A213 T5 Chrome Moly Tubeing Supplier

ASME SA213 T5B Alloy Steel Round Tubes

High Pressure Alloy T5 Seamless Tube Exporter

K41545 Alloy Steel Tubing

Grade T5B Alloy Steel Tubes Specification

T5 Alloy Steel Seamless Tube

T5C Alloy Steel Seamless Tubing

ASTM A213 T5 Chrome Moly Tubes

ASTM A213 Grade T5 Seamless Tube Manufacturer

Alloy Steel T5B Tubes Distributor

Alloy Steel T5 Cold Drawn Seamless Tubing

Alloy Steel T5C Seamless Tubes Price

Seamless Ferritic Alloy Steel T5 Tube

Alloy Steel UNS K41245 Tubes

Alloy Steel T5 Chrome Moly Tubes

A213 T5B Seamless Tubing Dealer

Alloy Steel UNS K51545 Seamlees Tube

ASTM A213 T5C Boiler Tubing

We have regular exports of Alloy Steel T5 Tubes in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of ASTM A213 T5 Alloy Steel Tubes in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.