+91 9820814560

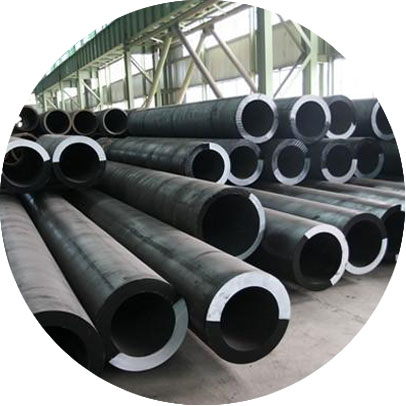

Steel Alloy Made of T9 alloy steel, which is renowned for its superior mechanical qualities and great performance in demanding applications, T9 tubes are a specific kind of tubing. T9 is a high-alloy steel that is strengthened, hardened, and resistant to wear and high temperatures by the addition of elements like chromium, molybdenum, and occasionally vanadium. Because of its remarkable tensile strength, T9 alloy steel is a good choice for situations where materials with a high mechanical stress tolerance are needed. One of the alloy's most notable qualities is its resistance to high temperatures. It is essential for applications such as heat exchangers and high-temperature pipelines because it retains its strength and structural integrity even in the presence of high temperatures.

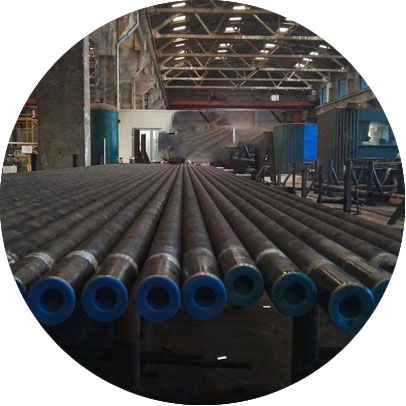

Because of the alloy's exceptional resistance to erosion and abrasion, components in high-wear situations have a longer lifespan. T9 tubes are frequently utilized in the oil and gas industry, especially in high-temperature and high-pressure settings like drilling equipment and pipelines. These tubes are used in power plants, particularly in the boiler and superheater tubes, where strength and heat resistance are essential.

To guarantee that the finished product fulfills strict quality standards, the production process for T9 alloy steel tubes entails careful control over alloying components and heat treatment procedures. Forging, rolling, and heat treatment are some of the procedures used to attain the appropriate mechanical qualities and dimensional precision.

Tube Specification : ASTM A213 / ASME SA213

Size : 1/2" NB To 36" NB

Outside Diameter (OD) : 19.05mm – 114.3mm

Wall Thickness : 2.0mm – 14 mm

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type : Seamless / EFW / Cold Drawn / Annealed & Pickled / Hot Finished / Extruded / Structural

Form : Round Tubes

Length : Single Random, Double Random & Cut Length

End : Plain End, Beveled End, Threaded

End Protection : Plastic Caps

Finish : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

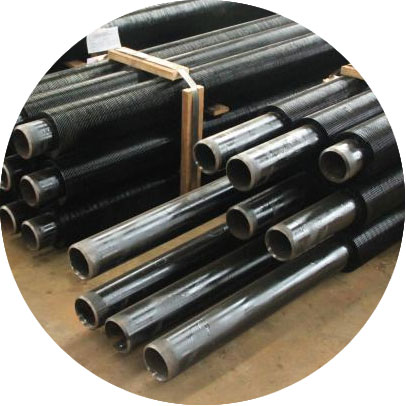

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM A213 T9 Alloy Steel Tubes at Best Price.

Call : +91-9820814560 or Send Enquiry

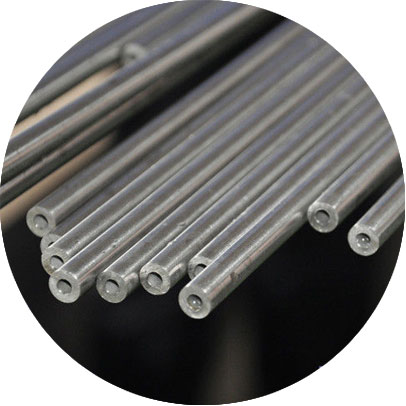

Alloy Steel T9 Seamless Tubes

Alloy Steel T9 High Pressure Steel Tubes

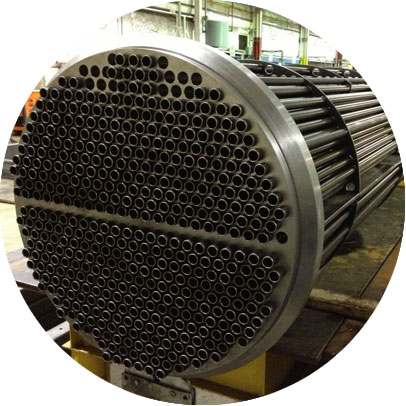

Alloy Steel T9 Heat-Exchanger Tubes

Alloy Steel T9 Superheater Tubes

Seamless Ferritic Alloy Steel T9 Tubes

Alloy Steel T9 Round Tubes

ASTM A213 T9 Chrome Moly Tubes

Alloy Steel T9 Boiler Tubes

| GRADE | UNS | TRADE NAME |

| T9 | S50400 | 9Cr-1Mo |

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.15 max | 0.30-0.60 | 0.025 | 0.025 max | 0.25-1.00 | 8.0-10.0 | 0.90-1.10 |

| Tensile Strength, MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

| 415 min | 205 min | 30 min | 179 max |

| Outside Diameter | OD Tolerance | WT Tolerance | Ovality Tolerance | Cut Length Tolerance |

| OD≤ 12, 7 mm | ± 0, 13 mm | ± 15 % | – | + 3, 18 mm, – 0 mm |

| 12, 7 mm < OD ≤ 38, 1 mm | ± 0, 13 mm | ± 10 % | max, 1, 65 mm | + 3, 18 mm, – 0 mm |

| 38, 1 mm < OD ≤ 88, 9 mm | ± 0, 25 mm | ± 10 % | max, 2, 41 mm | + 4, 76 mm, – 0 mm |

Alloy Steel T9 Tubes

Alloy Steel T9 Seamless Tube

Chrome Moly T9 Tubes

ASTM A213 CrMo T9 Tubing

T9 Alloy Steel Tubes

Alloy Steel ASTM A213 Gr T9 Tubes

Alloy Steel T9 Heat-Exchanger Tubes

Alloy Steel T9 Superheater Tubes Stockist

ASTM A213 T9 Chrome Moly Tubeing Supplier

ASME SA213 T9 Alloy Steel Round Tubes

High Pressure Alloy T9 Seamless Tube Exporter

S50400 Alloy Steel Tubing

Grade T9 Alloy Steel Tubes Specification

T9 Alloy Steel Seamless Tube

T9 Alloy Steel Seamless Tubing

ASTM A213 T9 Chrome Moly Tubes

ASTM A213 Grade T9 Seamless Tube Manufacturer

Alloy Steel T9 Tubes Distributor

Alloy Steel T9 Cold Drawn Seamless Tubing

Alloy Steel T9 Seamless Tubes Price

Seamless Ferritic Alloy Steel T9 Tube

Alloy Steel UNS S50400 Tubes

Alloy Steel T9 Chrome Moly Tubes

A213 T9 Seamless Tubing Dealer

Alloy Steel UNS S50400 Seamlees Tube

ASTM A213 T9 Boiler Tubing

We have regular exports of Alloy Steel T9 Tubes in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of ASTM A213 T9 Alloy Steel Tubes in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.