+91 9820814560

A nickel-molybdenum alloy called Hastelloy B2 is well known for its remarkable resistance to corrosive conditions, including hydrochloric acid. Because of its frequent usage in extremely corrosive industrial settings, it is perfect for parts like flanges, which are essential for joining and sealing pipe systems. Hastelloy B2 flanges' superior resistance to pitting, crevice corrosion, and stress-corrosion cracking—especially in reducing environments—are among their primary characteristics. Because of this, they can be used in hostile chemical environments and situations where other materials might not hold up. Hastelloy B2's strong resistance to corrosion is a result of its chemical makeup, which is mostly composed of nickel (30%) and molybdenum (approximately 60%).

In real-world settings, chemical processing, the petrochemical industry, and other fields where exposure to caustic chemicals is a problem frequently use Hastelloy B2 flanges. The durability and dependability of industrial systems depend heavily on their capacity to retain integrity in the face of harsh chemicals and high temperatures.

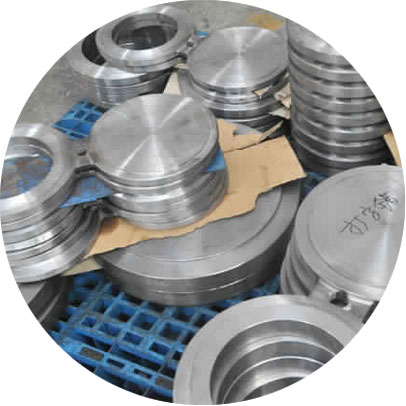

Forging, machining, and heat treating are some of the steps in the production process used to give Hastelloy B2 flanges the required mechanical qualities and dimensions. To satisfy certain technical needs, these flanges come in a range of diameters and pressure ratings. They also go through strict quality control procedures to guarantee that their performance and safety satisfy industry standards.

Specification : ASTM B564 / ASME SB564

Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Size : 1/2″NB TO 60″NB

Class : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)s

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM B564 Hastelloy B2 Flanges at Best Price.

Call : +91-9820814560 or Send Enquiry

| ASME/ANSI B 16.5 | Welding Neck Flange, Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Welding Neck Flange, Slip on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Hastelloy B2 Blind Flange

Hastelloy B2 Threaded Flange

Hastelloy B2 Orifice Flange

Hastelloy B2 Weld Neck Flange

Hastelloy B2 Slip on Flange

Hastelloy B2 Long Weld Neck Flange

Hastelloy B2 Spectacle Blind Flange

Hastelloy B2 Socket Weld Flange

| STANDARD | WERKSTOFF NR. | UNS |

| Hastelloy B2 | 2.4617 | N10665 |

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| B2 | 0.02 max | 1.0 max | 0.1 max | 0.03 max | 1.0 max | Bal | 1.0 max | 2.0 max | 26 – 30 | 0.04 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy B2 | 9.2 g/cm3 | 1370 °C (2500 ºF ) | Psi – 1,10,000 , MPa – 760 | Psi – 51000 , MPa – 350 | 40 % |

• B2 Hastelloy Threaded Flanges Price : US $50-200 / Piece ( FOB Price)

• Hastelloy B2 Pipe Flanges : US $1-100 / Kilogram ( FOB Price)

• ASME Standard Hastelloy B2 Plate Flanges : US $10-1000 / Unit ( FOB Price)

• UNS N10665 Hastelloy Forged Flanges : US $0.1-10000 / Piece ( FOB Price)

• Best Price Alloy B2 Weld Neck Flanges : US $13.2-35.4 / Piece ( FOB Price)

Hastelloy B2 Flanges are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a wide range of ASTM B564 B2 Nickel Alloy Screwed Flanges through a worldwide network of stock-keeping branches. These UNS N10665 Pipe Flanges is use in various industries like :

Hastelloy B2 BLRF Flanges use in Oil and Gas Industry

ASTM B564 B2 Hastelloy WNRF Flange use in Petrochemical Industry

B2 Hastelloy® Alloy Plate Flange Used In Refineries Industry

ASME B16.5 B2 Hastelloy Spacer use in Nuclear Power Plant Industry

B2 Nickel Alloy Puddle Flange use in Chemical Industry

Hastelloy® Alloy UNS N10665 Flexible Hose Flange use in Marine Industry

DIN 2.4617 Hastelloy Nippo Flange use in Aerospace Industries

ASTM B564 B2 Hastelloy Blind Flange use in Pulp & Paper Indusry

Hastelloy B2 Flange

Hastelloy B2 Threaded Flanges

Hastelloy B2 Socket weld Flanges

ASTM B564 Hastelloy B2 Slip on Flanges

B2 Hastelloy Weld Neck Flanges

Hastelloy B2 Lap Joint Flanges

Hastelloy B2 Blind Flanges

Alloy B2 Pipe Flanges Stockist

Alloy B2 Plate Flanges Supplier

ASME SB564 B2 Hastelloy Spectacle Blind Flange

ASME B16.5 B2 Hastelloy® Alloy Spacer

Hastelloy B2 Nippolet Flange

B2 Hastelloy Hydraulic SAE Flanges Exporter

N10665 Hastelloy® Alloy Flexible Hose Flange

2.4617 Hastelloy Tongue & Groove Flange Specification

B2 Hastelloy Orifice Flanges

B2 Hastelloy Forged Flanges

B2 Hastelloy SORF Flange

ASTM B564 Grade B2 Alloy Ring Type Joint Flange

Hastelloy B2 WNRF Flange Distributor

Hastelloy B2 Puddle Flange Nipple

Hastelloy B2 Long Weld Neck Flange Price

ASTM B564 B2 Hastelloy Square Flanges

Hastelloy UNS N10665 Loose Flanges

Hastelloy DIN 2.4617 Weldo Flange

B2 Hastelloy® Alloy Reducing Flanges

Hastelloy B2 Screwed Flanges Manufacturer

B2 Nickel Alloy RTJ Flanges Dealer

Nickel Alloy 2.4617 BLRF Flanges

Hastelloy® Alloy B2 Flanges

We have regular exports of Hastelloy B2 Pipe Flanges in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of ASTM B564 B2 Hastelloy Flanges in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.