+91 9820814560

High-performance nickel-chromium alloy Inconel 718 is well-known for its remarkable strength and durability to harsh conditions. Inconel 718 performs well in situations where other materials might not, and it is frequently used in gas turbines, aircraft, and high-temperature applications. Owing to its remarkable characteristics, it is a widely preferred option for producing coils, sheets, and plates. Different thicknesses of Inconel 718 sheets are available, offering versatility for a range of engineering applications. High tensile strength and resistance to oxidation and corrosion are well-known qualities of these sheets, which are essential for parts that are subjected to extreme temperatures and adverse environments. In aerospace engineering, they are frequently employed in the fabrication of rocket motor components, aircraft engine parts, and structural elements.

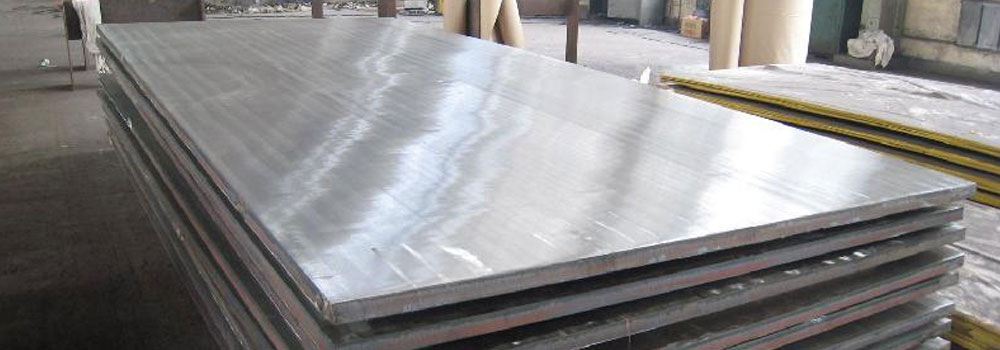

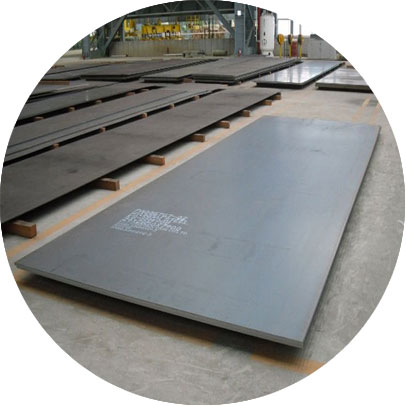

Similar advantages to the sheets are provided by Inconel 718 plates, which are usually thicker and utilized in situations that require for heavier materials. Because of their durability, these plates can be used for heavy-duty components in harsh environments, such as turbine blades and high-pressure seals. Reliability and lifespan are ensured by their superior fatigue resistance and capacity to maintain strength at high temperatures.

In industries where high strength, resilience to high temperatures, and resistance to corrosion are critical, Inconel 718 coils are very valuable. Rolling is the procedure used to create coils, which facilitates handling and allows for industrial flexibility. These coils are frequently employed in structural applications, heat exchanger manufacture, and other industries requiring continuous or semi-continuous lengths of material.

Specification : ASTM B670 / ASME SB670

Standard : JIS4304-2005, EN10088-2-2005, GB/T3280-2007, etc

Size : 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 7180 mm

Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

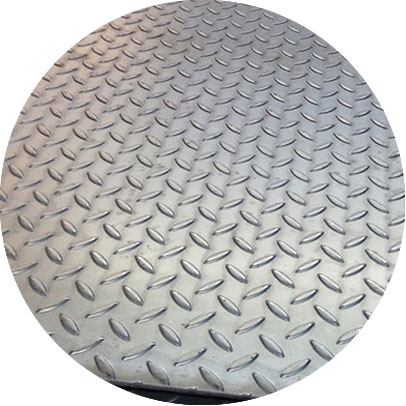

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Surface : 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM B670 Inconel 718 Sheets / Plates / Coils at Best Price.

Call : +91-9820814560 or Send Enquiry

Inconel 718 Shim Sheet

Inconel 718 Chequered Plate

Inconel 718 Perforated Sheets

Inconel 718 Hot Rolled Plates

Inconel 718 Cold Rolled Plates

Inconel 718 Coil

Inconel 718 Perforated Coil

Inconel 718 Foils

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel 718 | 2.4668 | N07718 |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015max | 0.30 max | - | 50.00 - 55.00 | 17.00 - 21.00 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

Inconel 718 Sheet

Inconel 718 Plate

Inconel 718 Coil

ASTM B670 Alloy 718 Shim Sheet

718 Inconel Chequered Plate

Inconel ASTM B670 718 Perforated Sheets

Inconel 718 Hot Rolled Plates

Alloy 718 Cold Rolled Plates Stockist

Inconel 718 Coil Supplier

ASME SB670 718 Inconel Perforated Coil

718 Inconel® Alloy CR Sheet

718 Inconel HR Sheet

ASME SB670 718 Inconel Strips

Inconel 718 Sheets

N07718 Inconel® Alloy Plates

2.4668 Inconel Coils Specification

718 Inconel Sheet

718 Inconel 2B Finish Sheet

718 Inconel #4 Finish Sheets

Inconel® Alloy 718 Foils

Grade 718 Nickel Alloy Plate

Inconel 718 Sheets Distributor

Inconel 718 Plates Price

Inconel UNS N07718 Sheet

Inconel DIN 2.4668 Plates

718 Inconel #8 Finish Plates

8 Mirror Finish 718 Inconel Sheet

Inconel 718 Sheet Manufacturer

718 Inconel Plates Dealer

718 Inconel Embossed Sheet Exporter

Nickel Alloy 2.4668 Sheets

Inconel 718 Laser Cutting Sheet

We have regular exports of Inconel 718 Plates in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of 718 Inconel Sheets / Plates / Coils in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.