+91 9820814560

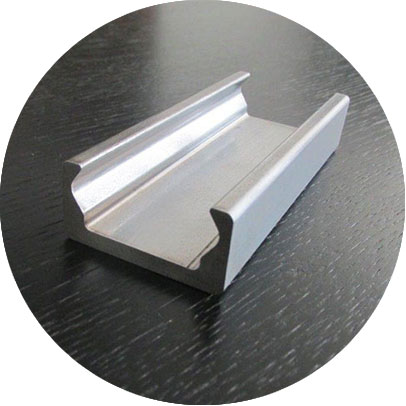

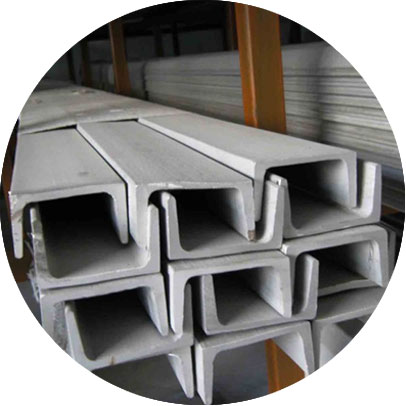

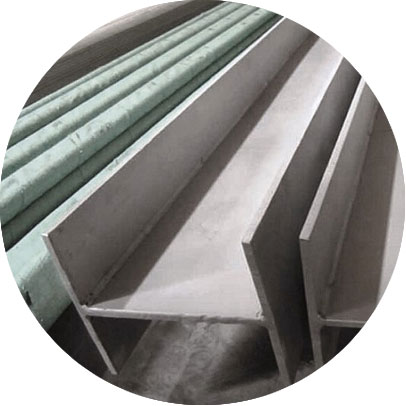

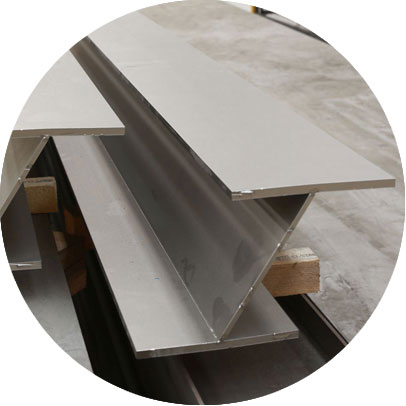

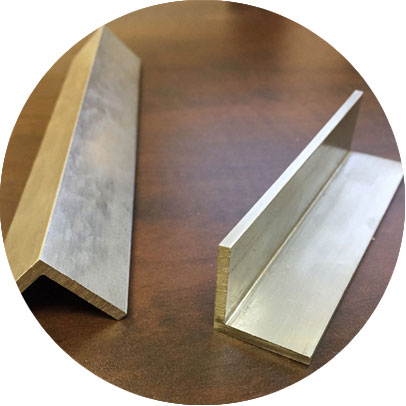

Structural forms like Incoloy 330 angles offer resilience and strength in harsh settings. These angles are employed in reinforcements, supports, and frameworks, especially in areas with high temperatures and corrosive environments. Even at high temperatures, the alloy's high chromium content aids in maintaining its mechanical qualities and resistance to oxidation and scaling. Structural elements having a U-shaped cross-section, Incoloy 330 channels are employed in many industrial and construction settings. Because of their exceptional strength and stability, they can be used as structural supports in challenging locations. In high-temperature applications, the alloy's resistance to oxidation and carburization assures life and lower maintenance. Large structural elements intended to sustain heavy loads and endure harsh environments are called Incoloy 330 beams. When used in high-temperature environments where other materials would degrade, they work perfectly. The alloy is a desirable option for beams in power plants and industrial plants due to its high mechanical strength and resistance to thermal degradation.

Incoloy 330 chains are utilized in settings with a lot of heat and corrosive circumstances. Compared to conventional chains, they provide better durability and oxidation and heat resistance. Because of this, they are appropriate for uses such as material handling in harsh environments and furnace operations.

The nickel-iron-chromium alloy Incoloy 330 is well known for its remarkable high-temperature resistance to carburization and oxidation. This alloy's durability and dependability make it a popular choice for a variety of high-temperature applications. It is particularly valuable in the petrochemical, aerospace, and power generation industries. In general, the durability and high-temperature characteristics of Incoloy 330 make it highly valued. Its many shapes, including as angles, beams, chains, and channels, offer dependable solutions for a variety of structural and industrial applications, guaranteeing performance and safety even in the most demanding circumstances.

Specification : ASTM B511 / ASME SB511

Size : 5 mm To 500 mm

Thickness : 50 mm to 6000 mm Long.

Length : 1 to 6 Meters, Custom Cut Lengthss

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM B511 Incoloy 330 Angle / Channel / Beam / Chain at Best Price.

Call : +91-9820814560 or Send Enquiry

Incoloy 330 Angle

Incoloy 330 C Channel

Incoloy 330 U Channel

Incoloy 330 H Beam

Incoloy 330 I Beam

Incoloy 330 Anchor Chain

Incoloy 330 Twist Link Chain

Incoloy 330 L Angle

| STANDARD | WERKSTOFF NR. | UNS | JIS |

| Incoloy 330 | 1.4886 | N08330 | NCF 330 |

| GRADE | C | Mn | P | S | Si | Cr | Ni | Mo | Cu | Fe | Sn | Pb |

| Incoloy 330 | 0.08 max | 2.00 max | 0.03 max | 0.03 max | 0.75-1.50 | 17.0-20.0 | 34.0-37.0 | 1.0-1.75 | 1.00 max | Balance | 0.025 | 0.005 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy 330 | 8.08 g/cm3 | 1380 °C (2520 °F) | 600 MPa | 280 MPa | 45 % |

Incoloy 330 Channel

Incoloy 330 Angle

Incoloy 330 Chain

ASTM B511 Incoloy® Alloy 330 Beam

330 Incoloy C Channel

ASTM B511 Incoloy 330 H Beam

Incoloy 330 I Beam

Alloy 330 T Beam Stockist

Alloy 330 Bar Angle Supplier

ASME SB511 330 Incoloy W Beam

330 Incoloy Equal Angles

330 Incoloy C Channel

ASME SB511 330 Incoloy L Angle

Incoloy JIS NCF 330 Unequal Angle

N08330 Incoloy Channel Bar

1.4886 Incoloy U Channel Specification

330 Incoloy Equal Leg Angle

330 Incoloy Lifting Chain

330 Incoloy Twist Link Chain

Incoloy 330 C Shape Channels

Grade 330 Incoloy U Shape Channel

Incoloy 330 Commercial Chain Distributor

Incoloy 330 Angle Price

Incoloy UNS N08330 Channel

Incoloy DIN 1.4886 Beam

330 Incoloy Cross Chains

330 Incoloy Chain Manufacturer

Incoloy Angle

330 Nickel Alloy Beam Dealer

Alloy 330 Channel Exporter

Incoloy 1.4886 Equal Angles

Incoloy 330 Chain

We have regular exports of Incoloy 330 Channel in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of 330 Incoloy Beam in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.