+91 9820814560

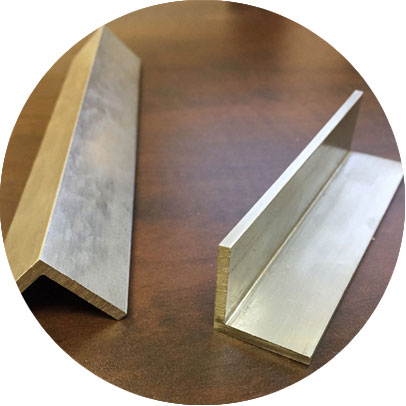

Inconel 625 angles provide excellent strength-to-weight ratios, making them perfect for use in supporting structures that must endure hard environments. Because of their resistance to oxidation and carburization, they have a longer lifespan and require less maintenance. Inconel 625 channels offer strong support in frameworks and structural assemblies, especially when resistance to corrosive substances and stability at high temperatures are essential. They are frequently used in the fabrication of parts for exhaust systems, high-temperature furnaces, and other high-stress settings. Inconel 625 beams are employed in a variety of load-bearing applications, giving buildings subjected to harsh environments strength and longevity. They are appropriate for industrial and aeronautical applications where performance under heat and stress is crucial because of their high tensile strength and resilience to thermal expansion.

Inconel 625 chains are employed in harsh settings, including the chemical industrial and maritime sectors. Their capacity to withstand corrosion, especially in acidic or salty environments, guarantees long-term dependability and reduces the chance of failure. All things considered, Inconel 625's special qualities guarantee that structural parts manufactured of this alloy retain performance and integrity even in the most extreme conditions, making it a useful material in high-demand industries.

High-performance nickel, chromium, and molybdenum alloy Inconel 625 is well-known for its remarkable resistance to harsh conditions and extremely high temperatures. It is the material of choice for many demanding applications because of its exceptional mechanical qualities and resistance to corrosion. Thanks to its exceptional strength and endurance, Inconel 625 performs exceptionally well when it comes to structural shapes like angles, channels, beams, and chains. In sectors including aerospace, maritime, chemical processing, and oil and gas, certain structural forms are essential.

Specification : ASTM B446 / ASME SB446

Size : 5 mm To 500 mm

Thickness : 50 mm to 6000 mm Long.

Length : 1 to 6 Meters, Custom Cut Lengthss

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM B446 Inconel 625 Angle / Channel / Beam / Chain at Best Price.

Call : +91-9820814560 or Send Enquiry

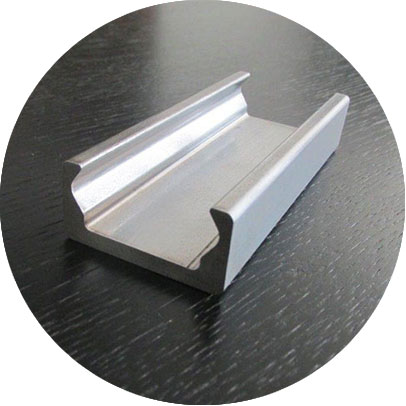

Inconel 625 Angle

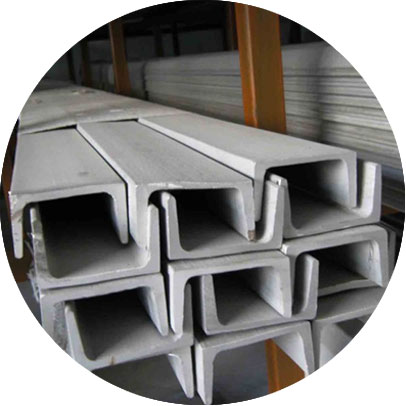

Inconel 625 C Channel

Inconel 625 U Channel

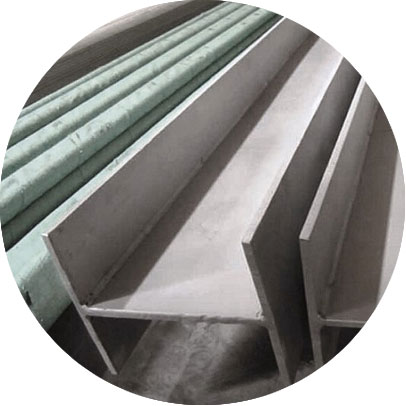

Inconel 625 H Beam

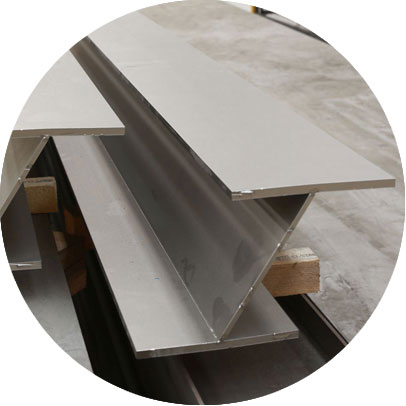

Inconel 625 I Beam

Inconel 625 Anchor Chain

Inconel 625 Twist Link Chain

Inconel 625 L Angle

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015max | - | 5.0 max | 58.0 min | 20.0 - 23.0 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Inconel 625 Channel

Inconel 625 Angle

Inconel 625 Chain

ASTM B446 Inconel® Alloy 625 Beam

625 Inconel C Channel

ASTM B446 Inconel 625 H Beam

Inconel 625 I Beam

Alloy 625 T Beam Stockist

Alloy 625 Bar Angle Supplier

ASME SB446 625 Inconel W Beam

625 Inconel Equal Angles

625 Inconel C Channel

ASME SB446 625 Inconel L Angle

Inconel JIS NCF 625 Unequal Angle

N06625 Inconel® Alloy Channel Bar

2.4856 Inconel U Channel Specification

625 Inconel Equal Leg Angle

625 Inconel Lifting Chain

625 Inconel Twist Link Chain

Inconel 625 C Shape Channels

Grade 625 Inconel U Shape Channel

Inconel 625 Commercial Chain Distributor

Inconel 625 Angle Price

Inconel UNS N06625 Channel

Inconel DIN 2.4856 Beam

625 Inconel Cross Chains

625 Inconel Chain Manufacturer

Inconel Alloy 625 Angle

625 Nickel Alloy Beam Dealer

Alloy 625 Channel Exporter

Inconel® Alloy 2.4856 Equal Angles

Inconel 625 Chain

We have regular exports of Inconel 625 Channel in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of 625 Inconel Beam in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.