+91 9820814560

The base alloy, Incoloy 800, is composed of 19–23% chromium, 30–35% nickel, and the remaining iron. Heat exchangers, furnace parts, and chemical processing machinery are among its main uses. It is an adaptable option for situations where thermal stability is crucial due to its resistance to oxidation and carburization at high temperatures. The purpose of the upgraded Incoloy 800H is to improve its creep and rupture strength at higher temperatures by adding carbon to the original Incoloy 800. It is appropriate for use in petrochemical and power generating industries where high temperatures and stress are common since it is made to retain mechanical qualities at temperatures as high as 1100°C (2012°F).With even higher carbon content and more alloying elements to improve creep resistance and overall performance at high temperatures, Incoloy 800HT is an even better version of Incoloy 800H. It is perfect for use in high-tech industrial settings where extended exposure to high temperatures is a concern, including gas turbines and heat treatment apparatus.

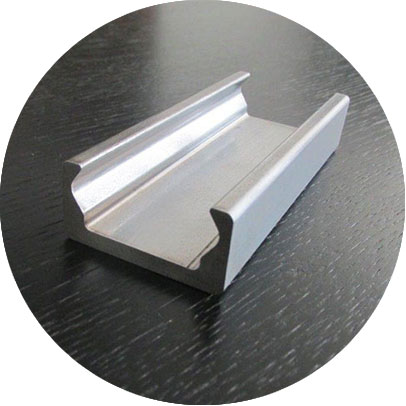

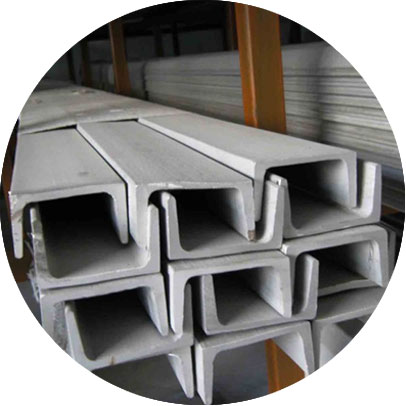

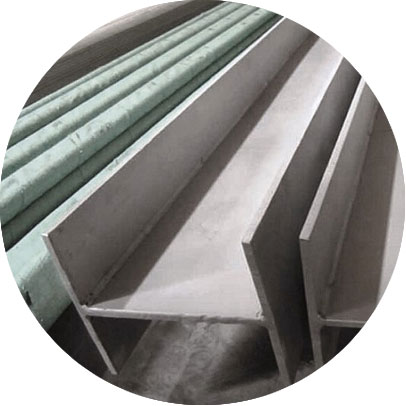

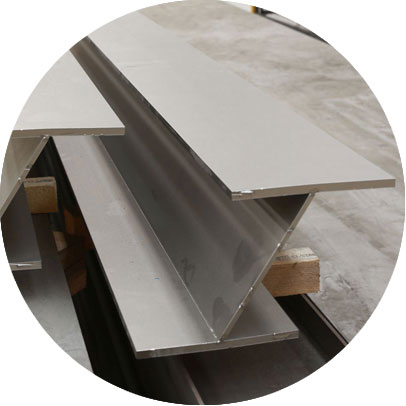

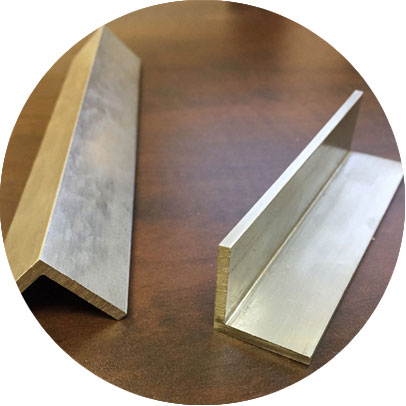

Angles, channels, beams, and chains are just a few of the shapes and forms that Incoloy 800, 800H, and 800HT come in. These shapes are employed in structural settings when it's necessary to have both mechanical strength and heat resistance. For instance, beams could be used in frames or supports in difficult settings, while angle and channel sections might be utilized in support structures for industrial equipment that operates at high temperatures. These alloys are used to make chains that are strong and corrosion-resistant in various applications.

High-performance nickel-chromium-iron alloys Incoloy 800, 800H, and 800HT are renowned for their superior resistance to oxidation, corrosion, and high temperatures. These alloys are widely employed in many different industries, including chemical processing, power generation, and aerospace, where stability and endurance are essential. All things considered, these Incoloy alloys provide a blend of stability at high temperatures and resistance to hostile environments, which makes them essential components in demanding industrial applications.

Specification : ASTM B408 / ASME SB408

Size : 5 mm To 500 mm

Thickness : 50 mm to 6000 mm Long.

Length : 1 to 6 Meters, Custom Cut Lengthss

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM B408 Incoloy 800 / 800H / 800HT Angle / Channel / Beam / Chain at Best Price.

Call : +91-9820814560 or Send Enquiry

Incoloy 800 / 800H / 800HT Angle

Incoloy 800 / 800H / 800HT C Channel

Incoloy 800 / 800H / 800HT U Channel

Incoloy 800 / 800H / 800HT H Beam

Incoloy 800 / 800H / 800HT I Beam

Incoloy 800 / 800H / 800HT Anchor Chain

Incoloy 800 / 800H / 800HT Twist Link Chain

Incoloy 800 / 800H / 800HT L Angle

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32 |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | - | X8NiCrAlTi32-21 | XH32T |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Incoloy 800 | 0.10 max | 1.50 max | 1.00 max | 0.015max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Incoloy 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Incoloy 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy 800 / 800H / 800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

Incoloy 800 Channel

Incoloy 800 Angle

Incoloy 800H Chain

ASTM B408 Incoloy® Alloy 800 Beam

800HT Incoloy C Channel

ASTM B408 Incoloy 800 H Beam

Incoloy 800 I Beam

Alloy 800H T Beam Stockist

Alloy 800 Bar Angle Supplier

ASME SB408 800HT Incoloy W Beam

800 Incoloy Equal Angles

800H Incoloy C Channel

ASME SB408 800 Incoloy L Angle

Incoloy JIS NCF 800 Unequal Angle

N08800 Incoloy Channel Bar

1.4876 Incoloy U Channel Specification

800 Incoloy Equal Leg Angle

800HT Incoloy Lifting Chain

800 Incoloy Twist Link Chain

Incoloy 800H C Shape Channels

Grade 800 Incoloy U Shape Channel

Incoloy 800 Commercial Chain Distributor

Incoloy 800HT Angle Price

Incoloy UNS N08810 Channel

Incoloy DIN 1.4859 Beam

800 Incoloy Cross Chains

800H Incoloy Chain Manufacturer

Incoloy Angle

800HT Nickel Alloy Beam Dealer

Alloy 800 Channel Exporter

Incoloy 1.4958 Equal Angles

Incoloy N08811 Chain

We have regular exports of Incoloy 800 Channel in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of 800 Incoloy Beam in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.