+91 9820814560

The strong corrosion resistance of stainless steel 317 pipes is well known, especially in settings with severe chemicals or chlorides present. This particular variety of stainless steel is a member of the austenitic family, which is renowned for its robustness and endurance. Iron makes up the majority of the alloy, with important components being nickel (11–15%) and chromium (16–18%), as well as molybdenum (3–4%). Compared to other stainless steel grades like 304 or 316, the addition of molybdenum improves the alloy's resistance to pitting and crevice corrosion, making it appropriate for usage in more harsh settings. Because 317 stainless steel pipes retain their mechanical qualities at high temperatures, they function very well in high-temperature applications, which is one of their key benefits. They are therefore perfect for sectors including petrochemical, pharmaceutical, and maritime applications where high heat is a problem. The pipes also have exceptional formability and weldability, making it simple to manufacture them into a variety of sizes and shapes.

These pipes are commonly used in applications that require exposure to acidic or chloride-rich environments. For example, they are employed in the construction of chemical processing equipment, heat exchangers, and marine structures. Their resistance to oxidation and scaling at high temperatures also makes them a preferred choice in industrial settings where these conditions are prevalent.

Compared to other grades, like 304 or 316, stainless steel 317 pipes are typically more expensive, despite their benefits. This is brought on by the more expensive raw materials and the intricate alloying procedure. But 317 pipes frequently outweigh the cost because to their better performance and longer lifespan, particularly in demanding applications where dependability and toughness are crucial.

Pipe Specification : ASTM A312, A358 / ASME SA312, SA358

Dimension Standard : ANSI B36.19M, ANSI B36.10

Outside Diameter (OD) : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size pipes available Ex-stock

Thickness Range : 0.3mm – 50 mm

Schedule : SCH 10, SCH20, SCH30, SCH40, STD, SCH60, XS, SCH80, SCH120, SCH140, SCH160, XXS

Type : Seamless Pipe, Welded Pipe, ERW Pipe, EFW Pipe, Fabricated Pipe, CDW

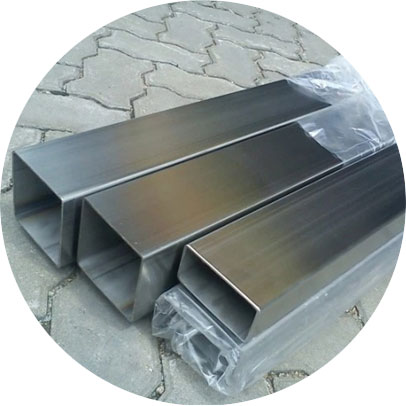

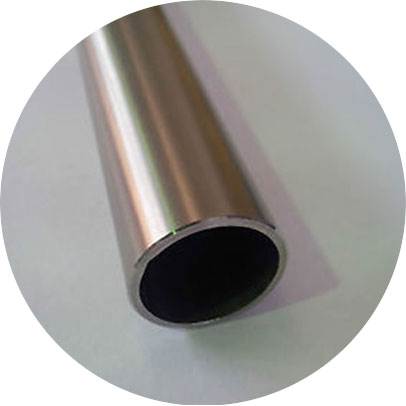

Form : Round Pipes, Square Pipes, Rectangular Pipe

Length : Single Random, Double Random & Cut Length

End : Plain End, Beveled End, Threaded

End Protection : Plastic Caps

Outside Finish : 2B, No.1, No.4, No.8 Mirror Finish

Finish : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

External Coating : 3LPE / 3LPP/ FBE/ DFBE/ PP

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM A312 TP 317 Stainless Steel Pipes at Best Price.

Call : +91-9820814560 or Send Enquiry

| NPS | OD | SCH 5S | SCH 10S | SCH 40S | SCH 80S |

| 1/4 | 13.72 | – | 1.65 | 2.24 | 3.02 |

| 3/8 | 17.15 | – | 1.65 | 2.31 | 3.2 |

| 1/2 | 21.34 | 1.65 | 2.11 | 2.77 | 3.73 |

| 3/4 | 26.67 | 1.65 | 2.11 | 2.87 | 3.91 |

| 1 | 33.4 | 1.65 | 2.77 | 3.38 | 4.55 |

| 1.25 | 42.16 | 1.65 | 2.77 | 3.56 | 4.85 |

| 1.5 | 48.26 | 1.65 | 2.77 | 3.68 | 5.08 |

| 2 | 60.33 | 1.65 | 2.77 | 3.91 | 5.54 |

| 2.5 | 73.03 | 2.11 | 3.05 | 5.16 | 7.01 |

| 3 | 88.9 | 2.11 | 3.05 | 5.49 | 7.62 |

| 3.5 | 101.6 | 2.11 | 3.05 | 5.74 | 8.08 |

| 4 | 114.3 | 2.11 | 3.05 | 6.02 | 8.56 |

| 5 | 141.3 | 2.77 | 3.4 | 6.55 | 9.53 |

| 6 | 168.28 | 2.77 | 3.4 | 7.11 | 10.97 |

| 8 | 219.08 | 2.77 | 3.76 | 8.18 | 12.7 |

| 10 | 273.05 | 3.4 | 4.19 | 9.27 | 12.7 |

| 12 | 323.85 | 3.96 | 4.57 | 9.53 | 12.7 |

| 14 | 355.6 | 3.96 | 4.78 | 9.53 | 12.7 |

| 16 | 406.4 | 4.19 | 4.78 | 9.53 | 12.7 |

| 18 | 457.2 | 4.19 | 4.78 | 9.53 | 12.7 |

| 20 | 508 | 4.78 | 5.54 | 9.53 | 12.7 |

| 22 | 558.8 | 4.78 | 5.54 | – | – |

| 24 | 609.6 | 5.54 | 6.35 | 9.53 | 12.7 |

| 26 | 660.4 | – | – | – | – |

| 28 | 711.2 | – | – | – | – |

| 30 | 762 | 6.35 | 7.92 | – | – |

Stainless Steel 317 Seamless Pipe

Stainless Steel 317 Welded Pipe

Stainless Steel 317 ERW Pipe

Stainless Steel 317 EFW Pipe

Stainless Steel 317 Electropolish Pipe

Stainless Steel 317 Square Pipe

Stainless Steel 317 Rectangular Pipe

Stainless Steel 317 Round Pipe

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | - |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Stainless Steel 317 Pipes

SS 317 Pipe

Stainless Steel 317 Pipe

Stainless Steel 317 Seamless Pipe

Werkstoff Nr. 1.4449 Pipe

Stainless Steel SUS 317 Pipes

Stainless Steel 317 Seamless Pipe

Stainless Steel TP 317 Pipe

ASTM A312 SS TP 317 Pipe

317 SS Welded Pipes

TP317 Stainless Steel 1/2" NB in Thickness Schedule 10 Pipes

ASTM A312 TP317 Pipe

TP 317 SS Square Pipe Exporter

1/4" OD in Thickness 10 Gauge, 12 Gauge, 20 Gauge Pipe

SS 317 EFW Pipes Stockist

ASME SA312 TP 317 Stainless Steel Round Pipes

S31700 High Precision Stainless Steel Pipe

Stainless Steel ASTM A312 TP317 Pipes

TP317 Stainless Steel Pipes

TP 317 Stainless Steel Welded Pipes

Stainless Steel 317 ERW Pipes

SS 317 Rectangular Pipes Supplier

ASME SA312 TP 317 Stainless Steel Round Pipe

317 Stainless Steel Pipe Specification

AISI 317 Stainless Steel Pipe

Stainless Steel 317 Pipe Price

Stainless Steel 317 Cold Drawn Seamless Pipe

TP 317 Stainless Steel Hexagonal Pipe

317 Stainless Steel Electropolished Pipe

317 Stainless Steel Seamless Pipe

Stainless Steel UNS S31700 Pipes

3/4" NB in Thickness Schedule 40, Schedule XXS Pipes

Fabricated Stainless Steel 317 Pipe Distributor

SS 317 Flexible Hose Pipe

TP 317 Stainless Steel Seamless Piping

S31700 SS Hexagonal Pipe

TP 317 SS Hallow Pipes Dealer

ASTM A312 Grade TP317 SS Seamless Pipe Manufacturer

ASME SA312 SS 317 ERW Pipe

TP 317 SS Bush Hex Pipe Dealer

Stainless Steel 317 Square Pipe

SS TP317 SS Flexible Hose Pipe

Stainless Steel SUS 317 Pipe

Stainless Steel TP 317 Hallow Pipe

Stainless Steel DIN 1.4449 Seamless Pipes

ASTM A312 TP 317 Stainless Steel Pipe

Large Selection of SS 317 Pipe

TP317 Stainless Steel Pipe

We have regular exports of Stainless Steel TP 317 Pipes in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of ASTM A312 TP 317 Stainless Steel Pipe in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.